Rimani aggiornato sui nostri prodotti

Iscriviti alla nostra newsletter

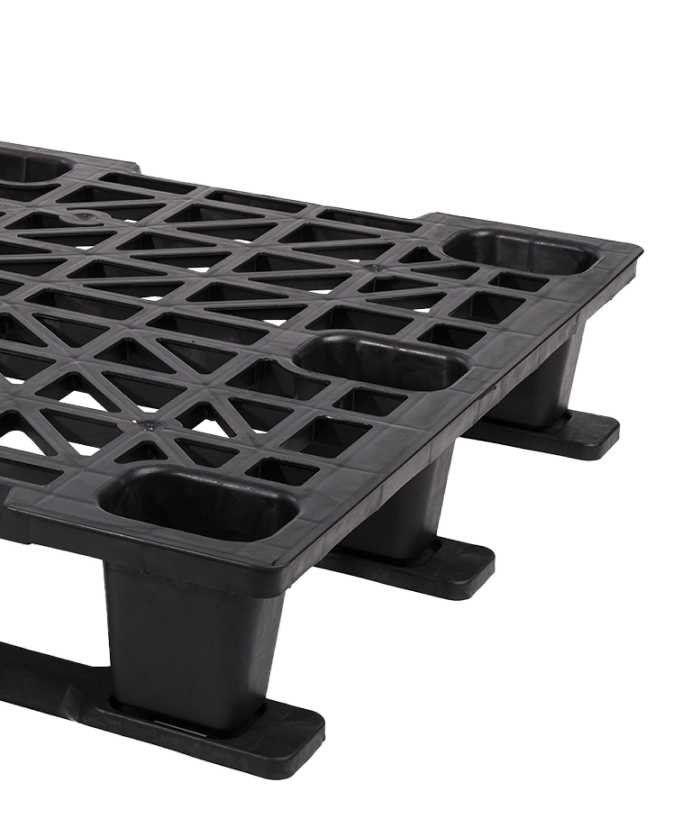

Since 2018, we have been manufacturing sustainable pallets and roll holder wedges made from 100% recycled and recyclable plastic sourced from industrial waste. Our greatest challenge is striving for a more ecological logistics system minimizing as much as possible single-use pallets.

By choosing our recycled plastic products one can obtain points for three of the objectives of the “Sustainable Development Goals” program promoted by the United Nations for sustainable development.

In addition to being environmentally friendly, our products offer many direct benefits that optimize your daily work.

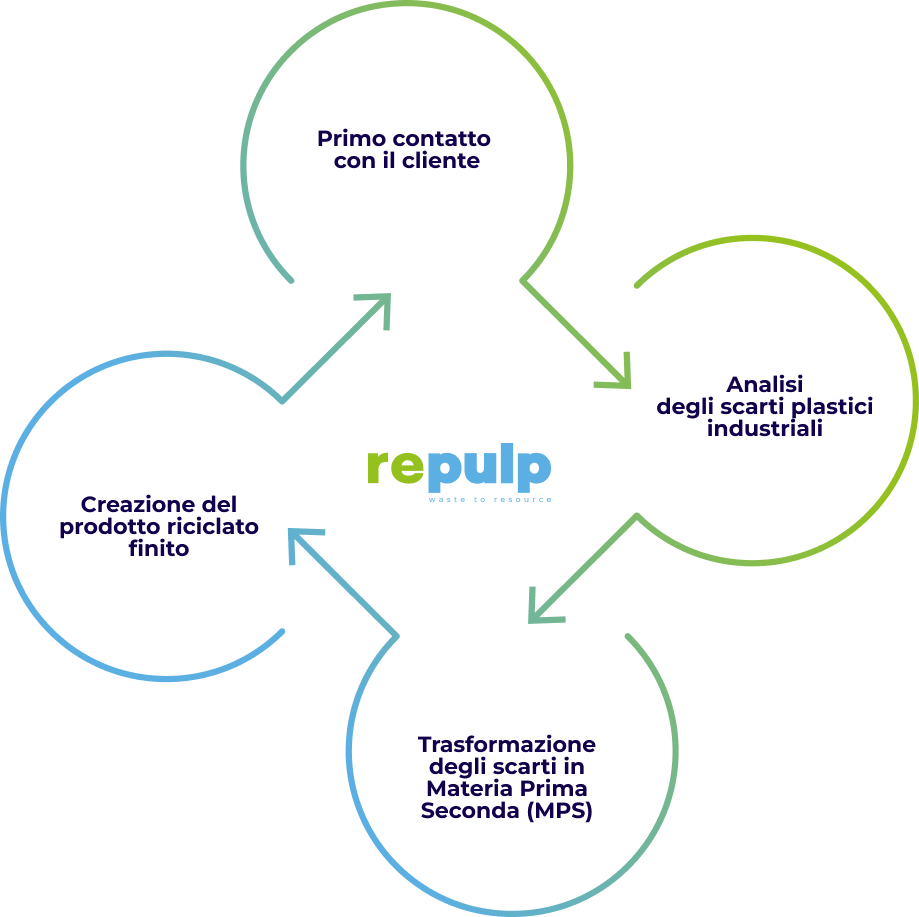

We evaluate our customers’ industrial waste to understand whether is possibile to use them in the production of new pallets. The old material never becomes waste; instead, it can be transformed to become a new reusable secondary raw material for the manufacturing new repulp products.

Our products help reduce the impact of logistics on the environment according to the principle of the circular economy.

Iscriviti alla nostra newsletter

Repulp S.r.l.

Via per Vicopelago, 257 | 55100 Lucca

tel. +39 0583 391451

info@repulp.it

P.IVA 02513690467

REA LU-231824

Capitale sociale 500.000,00 € i.v.

Seguici

Fill the form to download our LCA study