Rimani aggiornato sui nostri prodotti

Iscriviti alla nostra newsletter

I nostri r-Pallet contribuiscono a ridurre l’impatto della logistica sull’ambiente secondo il principio dell’economia circolare. Collaborando con noi, potrai diventare a tua volta portavoce di un’etica ambientale e anti-spreco con azioni concrete, abbattendo al tempo stesso i costi sul lungo periodo.

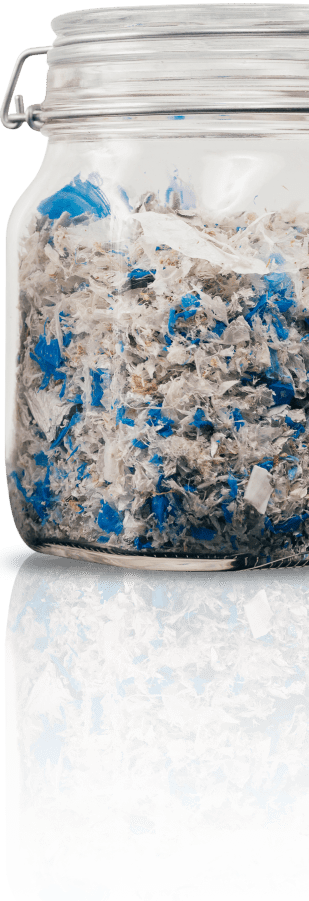

Riutilizziamo le plastiche altrimenti smaltite in discarica o nei termovalorizzatori per realizzare prodotti al 100% riciclati e riciclabili. I nostri r-Pallet nascono da una materia prima seconda, limitando in questo modo sia gli sprechi legati alle produzioni in legno, sia le emissioni relative all’uso di plastica vergine.

Il processo di nascita dei nostri r-Pallet a partire da poliolefine post-consumo e post-industriali si articola nelle fasi seguenti:

Gli scarti plastici si trasformano, gli r-pallet sono pronti per i loro viaggi!

Con la nostra attività ci impegniamo a promuovere un ciclo virtuoso di economia circolare.

La logistica che sogniamo non è più basata sull’usa e getta, ma sull’impiego multiplo dei nostri pallet che, a fine vita, possono essere nuovamente rigranulati e ristampati per realizzare nuovi prodotti. Durevoli e sostenibili.

Iscriviti alla nostra newsletter

Repulp S.r.l.

Via per Vicopelago, 257 | 55100 Lucca

tel. +39 0583 391451

info@repulp.it

P.IVA 02513690467

REA LU-231824

Capitale sociale 500.000,00 € i.v.

Seguici